CNC laser cutting

Laser cutting is a very precise technology to cut (stainless) steel or aluminium. The major advantage is great precision and clear lines without burrs. In C&F we are endowed with knowledge and experience for working with the laser machine to produce high volume and atypical orders while maintaining the highest quality standards.

- Higher speed and dynamics through linear drive technology

- Integrated pallet changer for sheet exchange within seconds

- Innovative procedures for rapid, reliable processing

- Outstanding edge quality without micro burrs or reworking

Description

We are equipped with a TRUMPF TruLaser 3030, the machine allows us to meet 100 % of your requirements.

TruLaser 3030 machine uses CoolLine technology helping to cut even the slightest details. Thanks to BrightLine technology, the cut lines will be clean and without burrs. The machine is equipped with a LoadMaster for automatic loading.

Parameters of production

- Machine: TRUMPF TruLaser 3030

- Sheet thickness: mild steel: 20 mm, stainless steel: 12 mm

- Maximum size: 1.500 × 3.000 mm

- Accuracy of the cut: 0.1 mm

Our products

Covers and segments for wind power turbines

A lot of various covers, segments, flanges or chassis of wind power turbines. It is all cut with maximal precision and speed, from small parts to complicated weldments.

Learn moreRealized operations

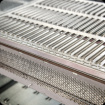

Segments of cooling devices

More complicated segment patterns are also usually laser-cut.

Learn moreRealized operations

Hood segment of wheel or belt loaders

Working with bigger products is not a problem for precise cutting and processing of complicated patterns.

Learn moreRealized operations

Covers and walkways of wheel or belt loaders

A strong emphasis is put on the quality of precise processing, namely in the field of semi-automotive as you can see on the examples of such products.

Learn moreRealized operations

Contact us

You can contact us by phone +420 321 737060, e-mail reception@cfmanufacturing.cz or by an online contact form.